Production:

Production Services:

North American Assembly currently runs production for Ford and GM including air boxes, switches, dome lamps, tail lamp assemblies and more. Specializing in assembly is our strong point. Although there are many suppliers that claim they offer assembly services, and do, as well as their core business of molding or stamping, no supplier can match the expertise and quality that we can provide. Many larger companies are choosing to outsource assembly operations due to cost advantages that come with doing business with a company like North American Assembly.

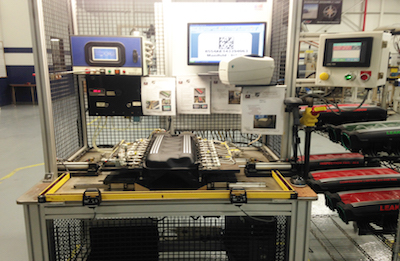

Production Equipment

We design, procure, debug and PPAP quality production equipment and processes. We provide turnkey operations for production programs at our facility or at your manufacturing facility. We have equipment fabrication expertise with the following manufacturing systems:

- Swaging, crimping, spinning operations

- Vibration and Ultrasonic welding

- Pressure decay and mass flow leak testing

- Synchronous assembly machines

- Power and free conveyor systems

- Processing operations with process controlled force transducers

- Completely automatic assembly dials ranging from 6 to 16 stations

- Automatic / semi-automatic process controlled DC drivers

- Modular cells and manual fixture complexes

- Paint Booth

- CNC secondary operations